Medical equipment

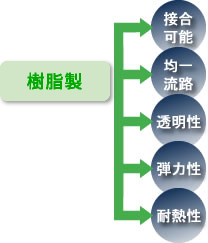

Ultra-fine processing by resin injection molding

Enabled by MicroResico®

Micro Resico® has made it possible to process unevenness of 1 to 100 μm by injection molding.

A substrate etched on a silicon wafer is used as a stamper to further control the fluidity of the resin.We made it possible to faithfully reproduce the unevenness of the etching process by injection molding.

By increasing the durability of the stamper, we have achieved mass production of ultra-fine processed products.Compared to conventional manufacturing methods using quartz glass, silicon wafers, and PDMS, this method is far superior in terms of reproducibility and cost.

Utilizing the characteristics of MicroResico®, a resin, it is possible to bond ultra-microfabricated products with high precision and strength.The joint surface is pressure resistant and prevents liquid leakage, so excellent microstructures and microcomponents can be made.The joint peeling test image is please use this form..

Unlike direct etching, the injection molded channels with MicroRecico® are very smooth and have a uniform depth.

How does it flow through the chip? please use this form. You can see it at.

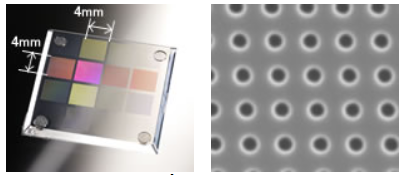

Utilizing the characteristics of Microresico® resin, products molded from Microresico® have excellent transparency (haze of 7% or less/120mm) and heat resistance (XNUMX°C), and microscopic observation with transmitted light is possible. has the necessary conditions.Also, since it is made of resin, it does not break and is easy to handle.

We accept requests for production of ultra-fine processed products using MicroResico®.

For details, please contact the following.

Contact

Richell Corporation

New Business Development Medical Device Department

TEL: 076-472-3058

FAX:076-472-3765

(Reception hours: excluding Saturdays, Sundays, holidays, and company holidays

Weekdays 9:00-17:00)

Web:Contact Form

/4mm square

Another example is please use this form. .

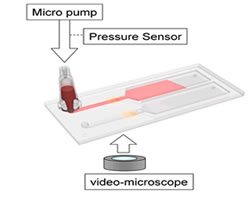

Adoption example

T-TAS, an analysis system developed by Fujimori Kogyo to quantitatively analyze the thrombus formation ability under blood flow with a small amount of whole blood,

A microresico® microchip with the following features was adopted.

(XNUMX) Even if whole blood flows through the channel, the liquid flows smoothly through the bonded portion without oozing out.

(XNUMX) Since injection molding is used, the reproducibility of the molded product (microchip) is high, and the production efficiency is also good.

Click here for the website of Fujimori Industry Co., Ltd. https://www.zacros.co.jp/

Click here for T-TAS page https://www.zacros.co.jp/product/t-tas01/