Die Division

Strengths of the Mold Division

30ton to 850ton

Mold making up to class

We have injection molding machines up to 1,300 tons

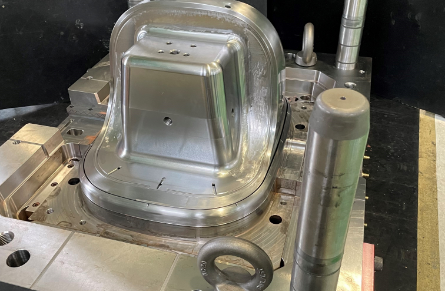

We design and manufacture various molds such as injection molding molds, blow molding molds, and rubber molding molds.

We have molding machines from 30 tons to 1300 tons and can mold prototypes.

Richell molds are of high quality and fast delivery

Good products are born from high-quality molds.

Richell achieves high-precision processing in microns.

From T1 to mass production, the number of trials can be reduced, and molds can be manufactured in a short delivery time.

Product shape proposal

From the product development stage, it is possible to verify problems predicted in molding through flow analysis and structural analysis.

By quantifying the verification results, it is possible to shorten the delivery time of mold manufacturing and reduce the cost of molded products.

Repair/Modification

Even for old molds or molds without drawings, model data can be created based on actual measurements, and repairs and modifications can be made.We can also handle molds that are not manufactured by us.