Die Division

Technical guide

Discharge/polish-less mold manufacturing

In order to realize electrical discharge/polishing-less machining for the purpose of reducing costs and improving accuracy, we carry out machining that makes maximum use of the technology and equipment we have cultivated so far.

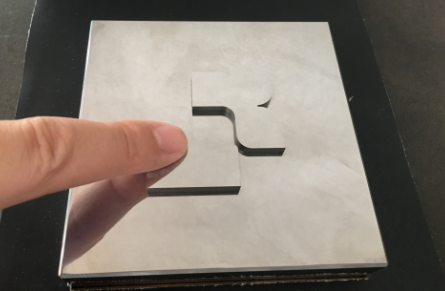

Precision wire electric discharge machining

This is an example of processing the logo mark of "Richell" by high-precision wire electric discharge machining.The clearance between the characters and the hole is 0.005mm or less, and the boundary line is invisible when the logo is in place.

Resin cutting prototype production

For customers who want to check the shape and function before making a mold, we provide a product prototype similar to the final product by resin cutting.

Material: PMMA (acrylic)

Achieves higher transparency than glass by utilizing polishing technology cultivated in mold manufacturing

Material: ABS

Tip diameter Φ0.3mm Height 9mm Number 224

Highly dense ultra-fine pin processed products that apply mold processing technology

Material: PC

A processed product that has mobility by manufacturing two curved parts and combining them.