story of plastic

Mold

What is a mold?

A mold, which is a mold into which melted material is poured, has a cavity that will become the product, and a flow path for the resin to flow into that cavity.In addition, it has an ejection mechanism for releasing the product from the mold.

Iron is the predominant material for the following reasons.

Injection pressure/

Resistant to clamping pressure

good workability

low cost

low specific heat

Aluminum and copper alloys are sometimes used to improve cooling efficiency and workability, but consideration must be given to rigidity and durability.

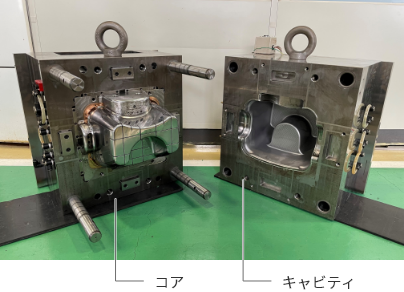

cavity

It is the fixed side that is attached to the molding machine and becomes the engraving surface of the female mold.

コ ア

It is the movable side of the mold. Generally, the core is the back side of the molded product, and it is equipped with an ejector plate and pins.

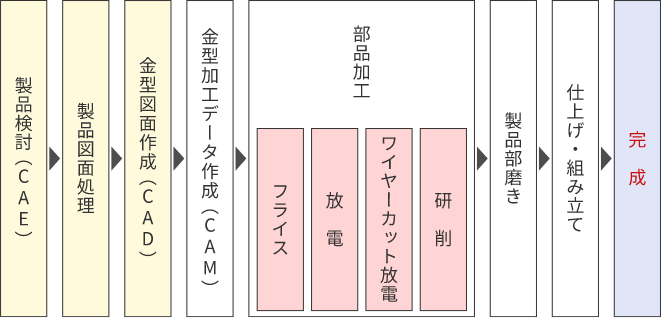

Mold making process

Following the process below, product blueprints are created, and molds are designed and manufactured based on them.

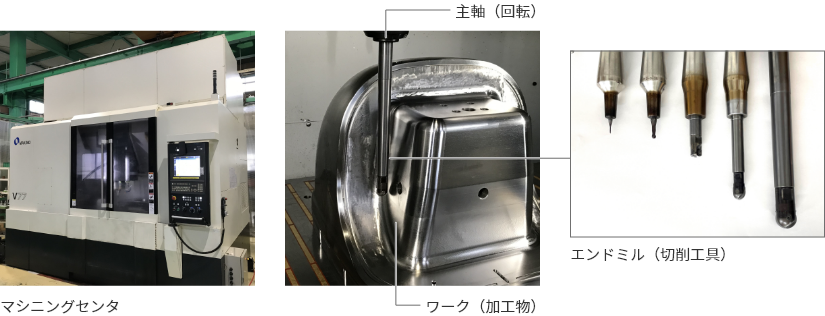

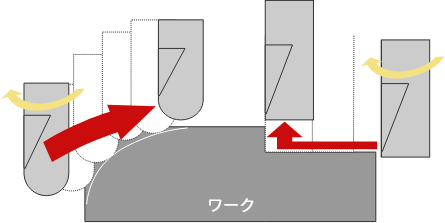

milling

A machining method in which a cutting tool attached to the tip of a spindle is rotated to cut an object (workpiece).

Strong Points

・High processing speed

・Heavy cutting is possible

Cons

・Highly affected by workpiece hardness

・Influenced by cutting tool accuracy

・There is a limit to the strength of cutting tools.

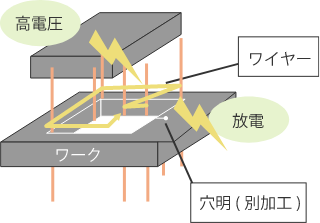

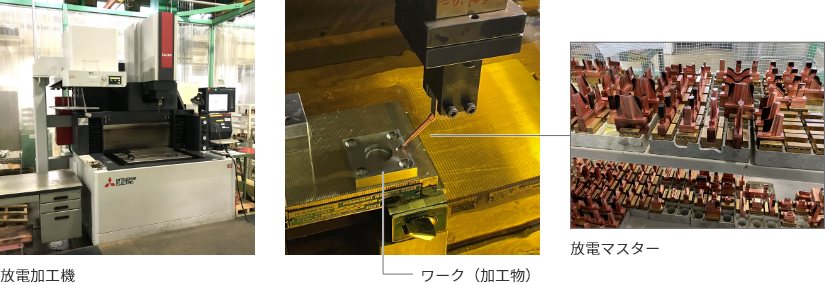

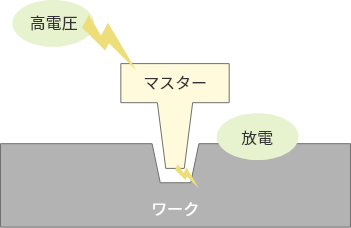

Electric discharge machining

A machining method in which arc discharge is generated between the electrode and the workpiece (work) to remove part of the surface of the workpiece.

Strong Points

・Easy to process thin parts

・It is possible to check the shape in advance with the master

・Less affected by workpiece hardness

Cons

・Processing speed is slow

・Master is required for separate processing

・Work must be conductive

・Shape of edge is not possible

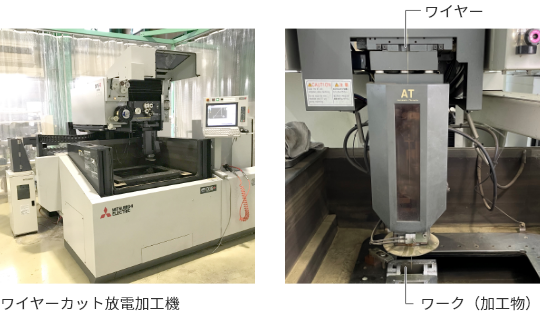

wire cut electrical discharge machining

A type of electrical discharge machining that uses thin wires as electrodes

Strong Points

・Easy to process thin parts

・It is possible to check the shape in advance with the master

・Less affected by workpiece hardness

Cons

・Work must be conductive

・Shape of edge is not possible