story of plastic

Mold

Malfunction of the molded product

A typical defect in injection molding is the appearance defect of the product as shown below.

These defects can be resolved by changing the setting conditions of the injection molding machine.

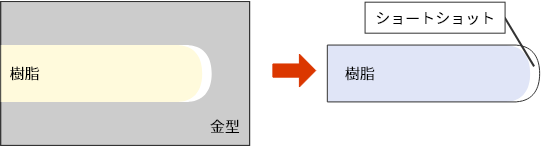

short shot

Phenomenon in which part of the molded product is not filled with resin.

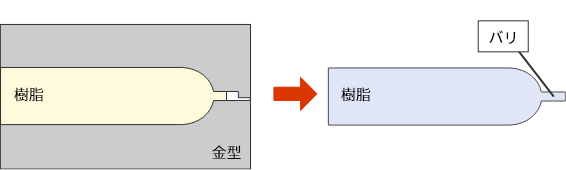

バ リ

There is a gap in the mold, and resin flows into the gap, resulting in excess thickness.

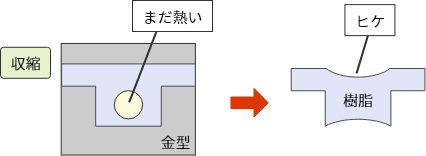

Sink

A phenomenon in which a part of a molded product shrinks more than its surroundings, resulting in a partial depression.

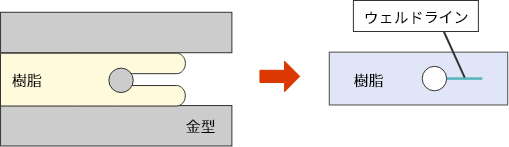

Weld line

Phenomenon where thin lines appear due to joints of resin flow.

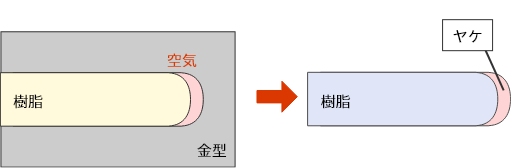

Discoloration

A phenomenon in which the air inside the mold is compressed by the injection pressure and becomes hot, burning the resin.

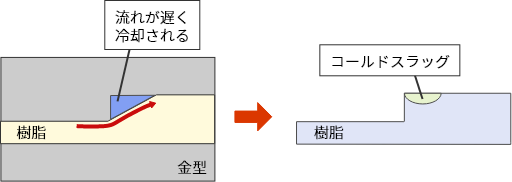

cold slug

A phenomenon that entrains cold resin when the direction and cross-sectional area of the resin flow change.