story of plastic

Mold

Mold classification (structure and gate)

As for the structure, there are mainly two-plate molds and three-plate molds, each of which has the following characteristics depending on the runner and gate method.

| Runner method | Gate method | Strong Points | Cons |

| cold runner | ト イ レ ク ト Gate |

・Low pressure loss due to gate ・Structure is simple, inexpensive, and hard to break |

・Gate cutting is required in the post-process ・Large gate cut marks ・Cannot take multiple pieces ・Cannot be multi-pointed |

| side gate | ・There is relatively little pressure loss due to the gate ・Structure is simple, inexpensive, and hard to break |

・Gate cutting is required in the post-process ・ Gate marks remain |

|

| submarine gate | ・No need for gate cutting in post-process | -Can only be installed on the side ・The gate marks are not convex, but they are dirty |

|

| Hot runner | Various | ・Since there is no runner, the amount of material used is small. | ・Complicated structure/expensive - It takes time to replace materials. |

Runner method: cold runner

| Gate method | Strong Points | Cons |

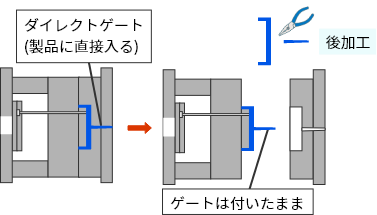

| ト イ レ ク ト Gate |

・Low pressure loss due to gate ・Structure is simple, inexpensive, and hard to break |

・Gate cutting is required in the post-process ・Large gate cut marks ・Cannot take multiple pieces ・Cannot be multi-pointed |

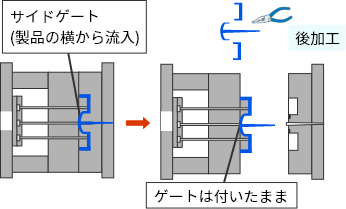

| side Gate |

・There is relatively little pressure loss due to the gate ・Structure is simple, inexpensive, and hard to break |

・Gate cutting is required in the post-process ・ Gate marks remain |

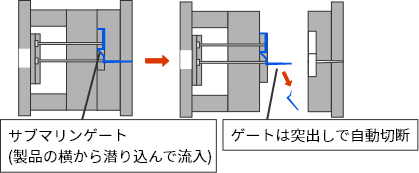

| submarine Gate |

・No need for gate cutting in post-process | -Can only be installed on the side ・The gate marks are not convex, but they are dirty |

Runner method: Hot runner

| Gate method | Strong Points | Cons |

| Various | ・Since there is no runner, the amount of material used is small. | ・Complicated structure/expensive - It takes time to replace materials. |

| Runner method | Gate method | Strong Points | Cons |

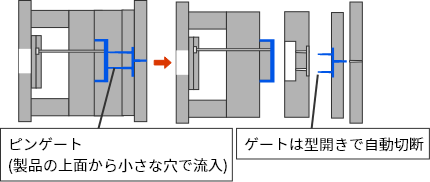

| cold runner | pin gate | ・No need for gate cutting in post-process ・The gate marks are small and inconspicuous ・Easy multi-point and multi-piece picking ・Even pressure distribution is easy to obtain | ・The amount of material used is large because the runner is long. ・Large mold size ・Complicated structure/expensive |

Runner method: cold runner

| Gate method | Strong Points | Cons |

| pin Gate | ・No need for gate cutting in post-process ・The gate marks are small and inconspicuous ・Easy multi-point and multi-piece picking ・Even pressure distribution is easy to obtain | ・The amount of material used is large because the runner is long. ・Large mold size ・Complicated structure/expensive |

mold structure

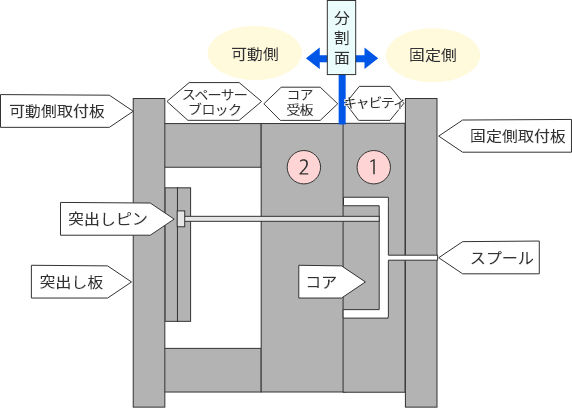

2 plate mold

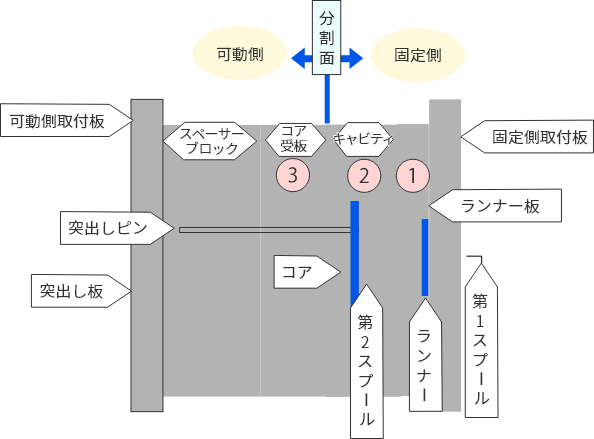

3 plate mold

The mold is divided into a fixed side and a movable side. The fixed side is always attached to the molding machine, and resin is injected from the spool at high pressure.

The movable side is the side that reciprocates to open and close. When injecting resin, it is closed with a pressure that can withstand the injection pressure, and after molding, it is opened to remove the molded product.

The mating surface of both mold plates is called the mold separation surface (parting surface).

The core support plate is provided to prevent the mold from bending due to injection pressure.

There are spacer blocks on both sides of the ejector plate to secure the area for the ejector plate to stroke between the core receiving plate and the movable side mounting plate.

The ejector plate is equipped with many ejector pins to eject the product.